Dust Collection Filter System

For Air / Gas Application

For Air and Gas application, Solid Dust is being collected through a system – Dust collector. Equipped with a Filter Housing, an Element Holding Plate to arrange different kind of designs of filter elements – Pleated kind with various fitment availability, Conventional design Filter Bag + Internal Supported Bag Cage + Venturi, Oval shaped holding plate design, Flat filter bag design etc., Manual or Automatic Operated Rotary Valve for drainage of collected dust, Pulsing Arrangement System consists of Solenoid valves, Compressed Air Tank, Timer or / and Control panel based cleaning arrangement.

Conventional Design of Dust Filter Bag

- Available in customized Available in customized sizes and fitment – through Snap band cuff, Spring steel ring, Collar fitment

- Length up to 10 m. available

- Filter Media will be Non Woven Polyester (Different GSMs as per application requirement), Conventional Aeramide, Glass Fiber, Carbon Media, PTFE, PPS with respect to application and operating parameters requirement.

- Flat Dia. Design of dust filter bag is also available.

- sizes and fitment – through Snap band cuff, Spring steel ring, Collar fitment

- Length up to 10 m. available

- Filter Media will be Non Woven Polyester (Different GSMs as per application requirement), Conventional Aeramide, Glass Fiber, Carbon Media, PTFE, PPS with respect to application and operating parameters requirement.

- Flat Dia. Design of dust filter bag is also available.

- Bags are available with suitable Filter Bag Cage of SS Gr., CS, GI perforation / Wire Mesh fabricated structure along with venture.

Pleated Design Dust Filter Bag

To increase the filtration area, pleated configuration of filter media is useful. Pleate dust filter bag has the top fitment with

- GI top cap with Snap Band cuff fitment

- EPDM top cap

- Natural Rubber top cap

- PU-Poluerethane top cap

- Spun Bonded Polyester Media (Plain)

- Spun Bonded Polyester + PTFE coating - to remove moisture content

- Spun Bonded Polyester + Antistic Coating

- Spun Bonded Polyester + PTFE Lamination

- Pleatable Aramide

- Outside Dia In 160mm

- Length in 500, 1000, 1400 & 2000mm

Medias Available are

Standard Sizes

Pleated Dust Filter Cartridge

As per Standard design, three different fitments are available for Pleated Dust Filter Cartridge. They are specified as –

MODEL 1 – Tie Bar Support Fitment from Bottom side of Element Holding Plate (Dirty Side Fitment)

MODEL 2 – Flat Flange Fitment from Top side of Element Holding Plate (Clean Side Fitment)

MODEL 3 – 3 / 4 Lug Fitment from Top side of Element Holding Plate (Clean Side Fitment)

3a. Tie Bar Fitment Pleated Dust Filter Cartridge

Medias Available are:

- Spun Bonded Polyester Media (Plain) - 260GSM

- Spun Bonded Polyester + PTFE Coating(260GSM) - to remove moisture content

- Spun Bonded Polyester + Antistatic Coating (260GSM)

- Spun Bonded Polyester + PTFE Lamination (260GSM)

- Pleatable Aramide

3b. Flat Flange Design

3c. 3 / 4 Lug Fitment Design

|

Sr. No.

|

OD of Filter x | Length (L1) | Length (L2) | Length (L3) |

| 1 | 150 | 500 | 1000 | 1400 |

| Filtration Area (m2) | 0.96 | 1.96 | 2.68 | |

| 2 | 225 | 500 | 1000 | 1400 |

| Filtration Area (m2) | 3 | 6 | 8.62 | |

| 3 | 325 | 500 | 1000 | 1400 |

| Filtration Area (m2) | 8 | 16 | 22.4 |

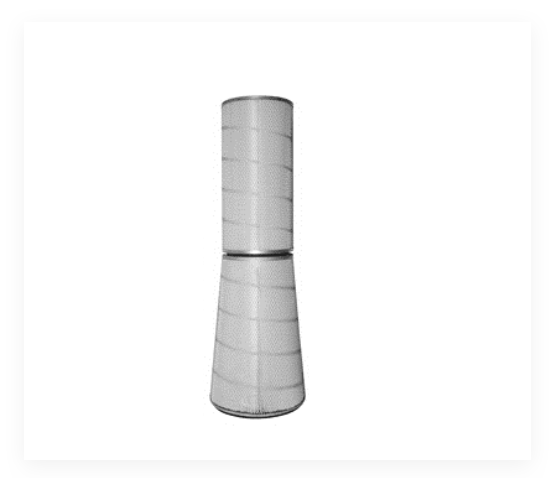

GT Air Intake Filter

For protection of turbine and compressor blades, suction air has been filtered through a set of Conical + Cylindrical filters are called GT Air in take Filters. Supported with inside and out side Expanded Mesh + Pleated configuration of 100% Cellulose Paper OR blend of 80% Cellulose + 20% Synthetic Filter media are used.

| Sl. No | OD | Length | Filtration Area ( m²) |

| 1 | 325 | 600 | 19 |

| 2 | 325 | 660 | 20 |

| 3 | 445 | 660 | 23 |